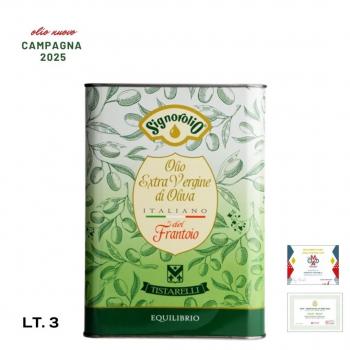

Extra virgin olive oil

~ in Tuscany ~

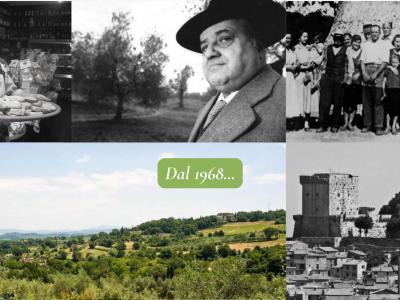

We are in Tuscany, and for four generations, we have dedicated ourselves with passion to the production of Extra Virgin Olive Oil .

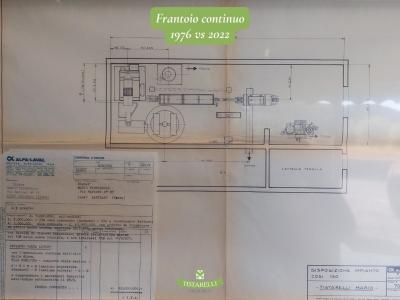

Our attention is focused on the olive groves, where we personally select the most prized olive varieties, and in our mill , where we employ the most advanced and innovative technology for cold extraction .

Our constant pursuit of excellence is fueled by passion, dedication, and the ongoing goal of achieving a delicate, fruity, and harmonious Extra Virgin Olive Oil, balanced in flavors.

We are pleased to invite you to our land, in Sarteano , on the hills of Siena, where the production of our Extra Virgin Olive Oil is an authentic expression of the territory, our culture, and the values we love to share.

The doors of our mill are always open , ready to welcome you and share with you the essence of our work and the goodness of its fruits.

Fausta Tistarelli

find out more

Our Products

~ Check out our Specialities ~

BUY SAFELY

~ How we like to work ~

-

Shipping

Do you have specific needs? Would you like to gift our oil? Write to us for information or a personalized quote!

-

Delivery Time

Transport carried out in 24/48h from the moment of purchase, depending on the delivery area.

-

Product

100% Made in Italy product, packaged for a safe and secure shipping.

-

Quality

Wide range of olive oil, accurately produced and extracted from the best Tuscan olive groves.

Blog & News

~ Latest News ~

/>

/>  />

/>  />

/>